Is Your Strategic Planning Truly Futuristic?

We read this Harvard Business Review (HBR) article, “How to Do Strategic Planning Like a Futurist,” and it immediately brought to mind the shared pain point we experience with industrial packaging prospects—some who become customers—and knew we had to write about it. Interestingly, we may be coming from slightly different perspectives here, but the end goal remains the same: plan, position, and prepare for the future and mitigate the risks that come with poor planning and outdated thinking.

We understand that transitioning to new packaging—specifically from traditional plastic pails to flexible bag-in-box or Meta® Pail  packaging—requires operational and equipment changes, financial considerations, and peripheral impacts within your supply chain, including manufacturing, distribution, and end-user concerns. It’s why we expertly guide you through the consultative process when considering this comprehensive shift in your packaging process.

packaging—requires operational and equipment changes, financial considerations, and peripheral impacts within your supply chain, including manufacturing, distribution, and end-user concerns. It’s why we expertly guide you through the consultative process when considering this comprehensive shift in your packaging process.

Here is where this HBR article we are citing comes in. We highly recommend you read the entire piece, as it offers real-life examples and solid how-to advice on new timeline perspectives to help you shift your thinking to plan for the future effectively. Here’s the rundown of the most salient points.

A Quantitative Futurist’s View

The author, Amy Webb, is a “quantitative futurist,” which means she investigates the future using data-driven models. She observes the current model this way: leadership teams get caught in a cycle of addressing long-term risk with rigid, short-term solutions, inviting entropy. Traditional linear timelines create a cycle of tactical responses to what feels like constant change being foisted upon stakeholders from outside forces. Over time, this takes significant internal alignment and effort and drains the organization’s resources, making them vulnerable to disruption.

Timelines: Dos and Don’ts

She talks about why it is best to avoid long-term timelines. We tend towards linear timelines because they offer more assurance and—perhaps a false sense of—control. Webb says, with linear timelines, we feel that “success can be plotted and guaranteed.” We all know this isn’t the case. As she explains it, “Regulatory actions or natural disasters are wholly outside of your control, while other factors—workforce development, operations, new product ideas—are subject to layers of decisions made throughout your organization. As all those variables collide, they shape the horizon.”

Futuristic thinking cautions that the decision makers—strategists and C-Suite teams—who guide organizational direction shouldn’t mistake vision and brainstorming for critical thinking about the future. One example Webb shares regards publishers that did not anticipate the existential crisis that mobile phones would impart on their viability and were not prepared for the devastating repercussions. They made a series of “short-term tactical responses (website redesigns, mobile apps) without ever developing a clear vision for the industry’s evolution.”

Do you see yourself in this cycle with industrial packaging?

Need to Break this Cycle?

Webb sees organizations get stuck in this perpetual cycle between strategy and tactics. Don’t mistake this “process” (because it really isn’t one) as serious planning for the future. As Webb has seen, it results in a counter-productive cycle of trying to catch up: to competitors, to new entrants, and to external sources of disruption.

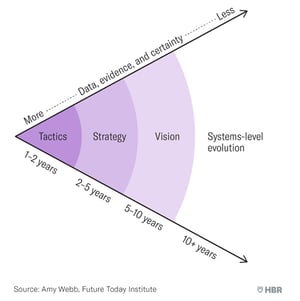

When working on foresight projects, she offers a new look at timelines—and calls them time cones. Build a cone with four distinct  categories. Here’s the breakdown:

categories. Here’s the breakdown:

- Tactics

- Strategy

- Vision

- Systems-level evolution

You begin with identifying highly probable events that have data to back them up—then work outward. Each section of the cone incorporates the one before it, until you eventually reach systems-level evolution in your organization. As Webb states, “Unlike a traditional timeline with rigid dates and check-ins, the cone always moves forward. As you gain data and evidence and as you make progress on your actions, the beginning of the cone and your tactical category is always reset in the present day. The result, ideally, is a flexible organization that is positioned to continually iterate and respond to external developments.”

It requires a willingness to accept some uncertainty and a continued recalibration of your organization’s vision for the future.

Webb admonishes, “If executive leaders do not have a strong sense of how their industry must evolve to meet the challenges of new technology, market forces, regulation, and the like, then someone else will be in a position to dictate the terms of your future.”

That can be a pretty harsh reality for people who are not forward-minded and willing and able to evolve.

How to Shift Your Mindset: A New Operation & Equipment Options

Here’s how this reality unfolds for us: this article is strikingly relevant to us because, for a variety of reasons, we hear how reticent people and organizations are to make the transition into flexible packaging. As stated above, we understand that there are concerns about equipment and process changes, and operational shifts that need to occur throughout the supply chain. We want you to know that we are experts at helping you make a smooth transition.

Financial justification is also a key component. Together, we will calculate the total cost of ownership, and ensure the Meta Pail solution meets your short- and long-term financial requirements. Additionally, we offer several purchase options, including leasing and product upcharge.

Once you’ve decided to shift to Meta Pail, CDF and WestRock will take the fear and guesswork out by providing pilot equipment for packaging validation and customer trials. After qualification, we will customize the right equipment solution to meet your production needs. Once installed, you will experience increased operational efficiencies and labor savings.

The Futuristic Mindset and Flexible Packaging

The direction that industrial packaging is headed tells us that you might very well be making these changes as a matter of course anyway. Consider starting now and be ahead the curve instead of someone else dictating the terms of your future. We’ve written various blogs about the future of packaging, which is undoubtedly transitioning to more flexible, sustainable, and end-user-friendly (yes, everyday consumers are driving this trend for B2B markets) packaging solutions.

With our disruptive packaging, we have positioned ourselves to embrace—truly shape—the future of bulk packaging. We offer

the Meta® Pail, bag-in-box, and UN-certified bag-in-box options for the safe, efficient storage and transport of semi-viscous, solid, and some liquid currently shipped in plastic pails. The sustainability profile of these products is impressive and various industries—chemical, cosmetic, pharmaceutical, food & beverage, and medical—benefit from the exceptional quality, function, and performance this flexible packaging provides.

Flexible Mindset

If you are ready to take a strategic step forward and plan your company’s future success with a new flexible packaging line, we’re happy to help. Contact us to get the conversation started.